Dalian Longyao Plastic Machinery Co., Ltd.

Contacts:Manager Xu

Mob:13354065688

Tel:0411-86268088

0411-86268988

BM:0411-86265066

Web:m.jingduwang.cn

Email :xu86268088@126.com

Add:Lushun lime kiln, Dalian, Liaoning Province

Dalian Longyao Plastic Machinery Co., Ltd.

Contacts:Manager Xu

Mob:13354065688

Tel:0411-86268088

0411-86268988

BM:0411-86265066

Web:m.jingduwang.cn

Email :xu86268088@126.com

Add:Lushun lime kiln, Dalian, Liaoning Province

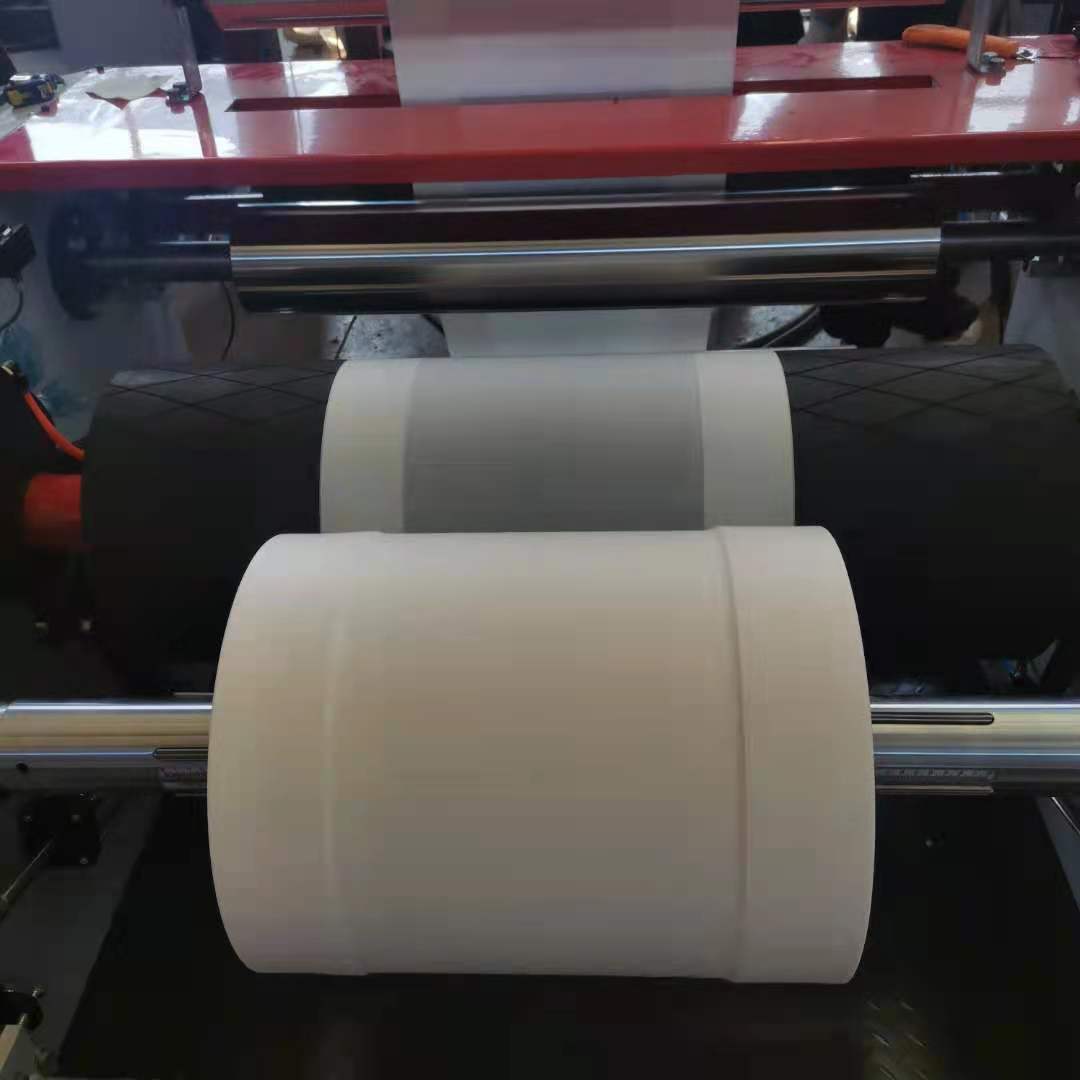

Key points of blow molding process control of film blowing machine

The process flow of blown film is roughly as follows:

Hopper feeding - material plasticization and extrusion → expansion traction → air ring cooling → herringbone splint → traction roller traction → corona treatment → film winding

However, it is worth noting that the performance of blown film is closely related to the production process parameters. Therefore, in the process of blowing film, it is necessary to strengthen the control of process parameters, standardize process operation, ensure the smooth progress of production and obtain high-quality film products. During the production of polyethylene blown film, the following process parameters are mainly controlled:

1. Extruder temperature

When blowing low density polyethylene (LDPE) film, the extrusion temperature is generally controlled between 160 ℃ ~ 170 ℃, and the temperature of the head of the film blowing machine must be uniform. If the extrusion temperature is too high, the resin is easy to decompose, and the film is brittle, especially the longitudinal tensile strength is significantly reduced; If the temperature is too low, the resin plasticization is poor, and the expansion and stretching cannot be carried out smoothly. The tensile strength of the film is low, and the gloss and transparency of the surface are poor. There are even patterns like wood rings and unmelted crystal nuclei (fish eyes).

2. Expansion ratio

The blowing ratio is one of the key control points of the blown film production process, which refers to the ratio between the diameter of the blown film bubble and the diameter of the non blown pipe ring. The expansion ratio is the transverse expansion multiple of the film, which is actually the transverse stretching of the film. The stretching will have a certain degree of orientation effect on plastic molecules, and the expansion ratio increases, so as to improve the transverse strength of the film. However, the blowing ratio should not be too large, otherwise it is easy to cause membrane bubble instability and membrane wrinkles. Therefore, the expansion ratio should be properly matched with the traction ratio. Generally speaking, the expansion ratio of low density polyethylene (LDPE) film should be controlled at 2.5 ~ 3.0.

3. Traction ratio

The traction ratio refers to the ratio between the traction speed of the film and the extrusion speed of the tube ring. The traction ratio is the longitudinal tensile multiple, which makes the film directional in the drawing direction. When the traction ratio increases, the longitudinal strength will also increase, and the thickness of the film will become thinner. However, if the traction ratio is too large, the thickness of the film is difficult to control, and even the film may be pulled apart, resulting in film breakage. The traction ratio of low density polyethylene (LDPE) film is generally controlled between 4 and 6.

4. Dew point

Dew point, also known as frost line, refers to the dividing line of plastic from viscous flow state to high elastic state. In the film blowing process, low density polyethylene (LDPE) is in a molten state when extruded from the die, with good transparency. After leaving the die, the expansion area of the film bubble shall be cooled through the cooling air ring. When the cooling air blows to the plastic film bubble just extruded from the die at a certain angle and speed, the high-temperature film bubble contacts with the cooling air, the heat of the film bubble will be taken away by the cold air, and its temperature will obviously drop below the viscous flow temperature of low-density polyethylene (LDPE), This allows it to cool, solidify and become blurred. On the blown film bubble, we can see a boundary between transparency and fuzziness, which is the dew point (or frost line).

In the film blowing process, the dew point has a certain impact on the film properties. If the dew point is high and located above the blown film bubble, the film is blown in the liquid state. The blown film only thins the film, and the molecules are not subject to tensile orientation. At this time, the performance of the blown film is close to that of the cast film. On the contrary, if the dew point is relatively low, the expansion is carried out in the solid state. At this time, the plastic is in the high elastic state. The expansion is like transverse stretching, which makes the molecules oriented, so that the performance of the expanded film is close to that of the oriented film.

Contacts:Manager Xu

Mob:13354065688

Tel:0411-86268088/0411-86268988

BM:0411-86265066

Web:m.jingduwang.cn

Email :xu86268088@126.com

Add:Lushun lime kiln, Dalian, Liaoning Province

Mobile station

Copyright ?Http://m.jingduwang.cn/En/ Dalian Longyao Plastic Machinery Co., Ltd Specializing inPE Film Blowing Machine,Three Layer Coextrusion Film Blowing Machine,ABA Film Blowing Machine, Welcome to inquire!

遼ICP備14017684號(hào) Powered By Xiangyun platform Technical support: joint enterprise Era