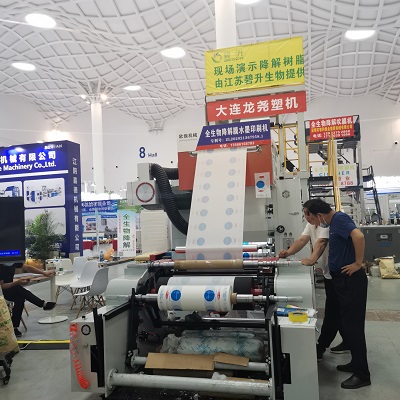

Dalian Longyao Plastic Machinery Co., Ltd.

Contacts:Manager Xu

Mob:13354065688

Tel:0411-86268088

0411-86268988

BM:0411-86265066

Web:m.jingduwang.cn

Email :xu86268088@126.com

Add:Lushun lime kiln, Dalian, Liaoning Province

Dalian Longyao Plastic Machinery Co., Ltd.

Contacts:Manager Xu

Mob:13354065688

Tel:0411-86268088

0411-86268988

BM:0411-86265066

Web:m.jingduwang.cn

Email :xu86268088@126.com

Add:Lushun lime kiln, Dalian, Liaoning Province

ABA film blowing machine is a common plastic film blowing equipment that can be used to produce various plastic films, including bubble films. Bubble film is a lightweight plastic packaging material with excellent cushioning performance, widely used in packaging, protection, and filling fields. With appropriate adjustment of process parameters, ABA blow film machines can also produce bubble films of different sizes, thicknesses, and special functional requirements to meet the needs of different industries for bubble films.

The structural characteristics of ABA film blowing machine are suitable for the production of bubble film. The ABA film blowing machine adopts a three-layer co extrusion film blowing structure, which can achieve the production of bubble films with different functions by controlling the thickness of different layers of film material. Among them, the A and B layers generally use low-density polyethylene (LDPE) or high-density polyethylene (HDPE) as raw materials, while the middle A layer is made of soft low-density polyethylene (EVA) or ethylene acetate copolymer (EVA) materials to increase the flexibility and buffering performance of the bubble film. The three-layer co extrusion structure can make the bubble film have both pressure resistance and impact resistance, meeting the packaging needs of different fields for bubble film.

Bubble film has some special physical properties, which can be met by ABA film blowing machine. Firstly, the softness of the bubble film. Bubble film needs to have a certain degree of flexibility and flexibility to adapt to various packaging shapes and requirements. The ABA film blowing machine adopts a three-layer co extrusion structure. By adding soft materials such as EVA to the film material, the softness and plasticity of the bubble film can be increased.

The buffering performance of bubble film. Bubble film is generally used to protect packaging items and has good cushioning performance. The ABA film blowing machine can adjust parameters such as the thickness of the film material and the size of bubbles to achieve a certain buffering effect on the bubble film. Once again, the transparency of the bubble film. Bubble film generally requires good transparency to display the appearance of the packaged item. The ABA blow film machine can control the extrusion and stretching processes to achieve better transparency and smoothness of the bubble film.

The processing technology of ABA film blowing machine is suitable for the production of bubble film. The ABA film blowing machine can control the thickness, width, and density of the bubble film by adjusting parameters such as extrusion speed, temperature, and die pressure. Due to the need for a certain thickness and uniformity of the bubble film, ABA blow molding machines can optimize the extrusion process to ensure good consistency and stability of the bubble film during the production process.

Contacts:Manager Xu

Mob:13354065688

Tel:0411-86268088/0411-86268988

BM:0411-86265066

Web:m.jingduwang.cn

Email :xu86268088@126.com

Add:Lushun lime kiln, Dalian, Liaoning Province

Mobile station

Copyright ?Http://m.jingduwang.cn/En/ Dalian Longyao Plastic Machinery Co., Ltd Specializing inPE Film Blowing Machine,Three Layer Coextrusion Film Blowing Machine,ABA Film Blowing Machine, Welcome to inquire!

遼ICP備14017684號(hào) Powered By Xiangyun platform Technical support: joint enterprise Era