Dalian Longyao Plastic Machinery Co., Ltd.

Contacts:Manager Xu

Mob:13354065688

Tel:0411-86268088

0411-86268988

BM:0411-86265066

Web:m.jingduwang.cn

Email :xu86268088@126.com

Add:Lushun lime kiln, Dalian, Liaoning Province

Dalian Longyao Plastic Machinery Co., Ltd.

Contacts:Manager Xu

Mob:13354065688

Tel:0411-86268088

0411-86268988

BM:0411-86265066

Web:m.jingduwang.cn

Email :xu86268088@126.com

Add:Lushun lime kiln, Dalian, Liaoning Province

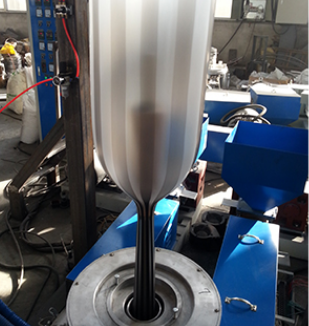

The reasonable and scientific control of the temperature of the plastic PE film blowing machine is more conducive to better film blowing, and the blown film can achieve the expected quality goals. But how to control the temperature of the plastic film blowing machine to better blow the film? Let me understand the effect of temperature on the blow film.

The film made of plastic film blowing machine can be widely used for light and heavy packaging because of its good barrier, freshness, moisture, frost, oxygen and oil resistance. Such as various fresh fruits, meat products, pickles, fresh milk, liquid drinks, medical supplies and other fields are widely used. In order to facilitate the film lifting and normal film blowing of the film blowing machine, the temperature of the film blowing machine needs an optimal temperature, and how to control this temperature.

Due to the different structure of the barrel screw of the film blowing machine and the different raw materials used, the set temperature during the mold blowing is also different. Generally, the temperature is set in accordance with the curve from low to high on the barrel, and slightly lower the temperature in the melting section to slightly raise the temperature in the mold.

According to the melting theory of plastics, the extruder screw for blown film is divided into three sections: feeding section, melting section and homogenizing section. At the end of the feeding section, when entering the melting section, according to the melting theory, its temperature should be the viscous flow temperature.

Temperature requirements of feeding section

At the inlet of the feeding section, it is hoped that the temperature will be lower to prevent the resin flow from blocking the feeding port. In addition, the resin will be continuously compressed in the feeding section, and the air will be discharged from the feeding port in reverse. According to different equipment structures, although the feeding port is not electrically heated, the temperature of the feeding port is about 50-90 ℃ through the heat transfer of the barrel. In this way, the temperature of the feeding section is determined. The temperature at the entrance is 50-90 ° C, and the end is equal to the melting point or viscous flow temperature. The temperature can be set at the section for linear temperature rise.

Melting section temperature requirements

At the beginning of the melting section, the temperature can only be melted when it reaches the viscous flow temperature. For crystalline resin, the viscous flow temperature is equal to the melting point temperature. Then, if the melting layer is continuously compressed and increased, the temperature needs to be constantly increased to make the length of the resin molecular chain vary. Polymers with different thermal motion energies are melted successively. Therefore, after the temperature at the end of the melting section is established, it can be determined that other parts of the section are heated linearly.

Contacts:Manager Xu

Mob:13354065688

Tel:0411-86268088/0411-86268988

BM:0411-86265066

Web:m.jingduwang.cn

Email :xu86268088@126.com

Add:Lushun lime kiln, Dalian, Liaoning Province

Mobile station

Copyright ?Http://m.jingduwang.cn/En/ Dalian Longyao Plastic Machinery Co., Ltd Specializing inPE Film Blowing Machine,Three Layer Coextrusion Film Blowing Machine,ABA Film Blowing Machine, Welcome to inquire!

遼ICP備14017684號 Powered By Xiangyun platform Technical support: joint enterprise Era